Oral Mechanic Lorry Test Prep Course

This course is specifically designed for drivers preparing for the oral mechanic lorry test. You’ll get 7 days of full access to clear and straightforward lessons, 6 quizzes covering the exact topics you’ll be tested on plus a realistic mock test so you know what to expect on test day.

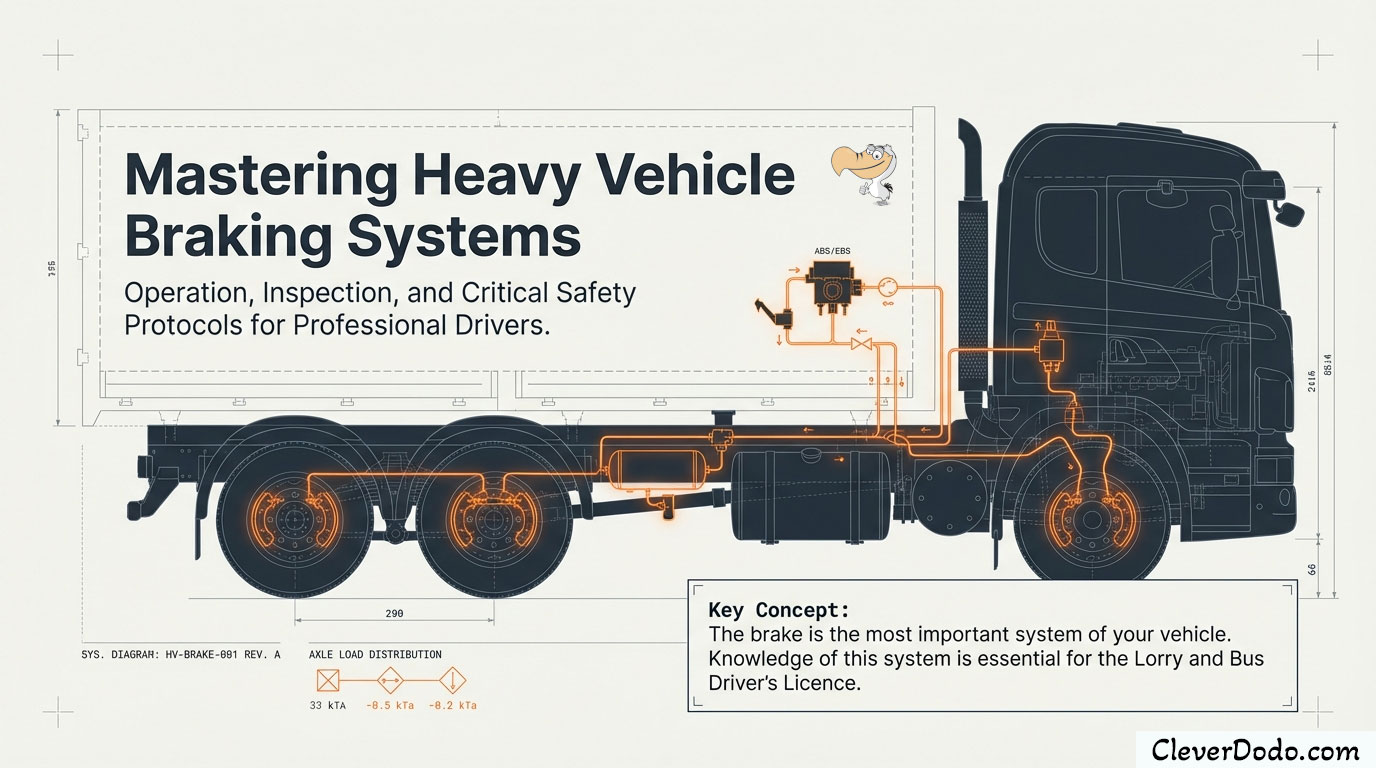

Braking Systems of Heavy Good Vehicles

Your brake pedal is one of the most important thing in your lorry. It can save lives!

And when driving a heavy vehicle, it matters even more.

The physics and design principles around the braking mechanism involve a lot of complex engineering that you don't need to know but having a good understanding of how it works is crucial not only to pass your oral mechanic test but also for your safety as well as others.

On Big Rigs, Losing Pressure Means Brakes On, Not Off

One of the most common fears in driving is a total brake failure—pressing the pedal and getting no response. However, the air brake systems used in heavy vehicles are engineered with a brilliant failsafe that works in the exact opposite way you might think.

These systems use incredibly powerful springs to physically apply the brakes to the wheels. The primary job of the compressed air in the system is not to apply the brakes, but to hold these powerful springs back, keeping the brakes released.

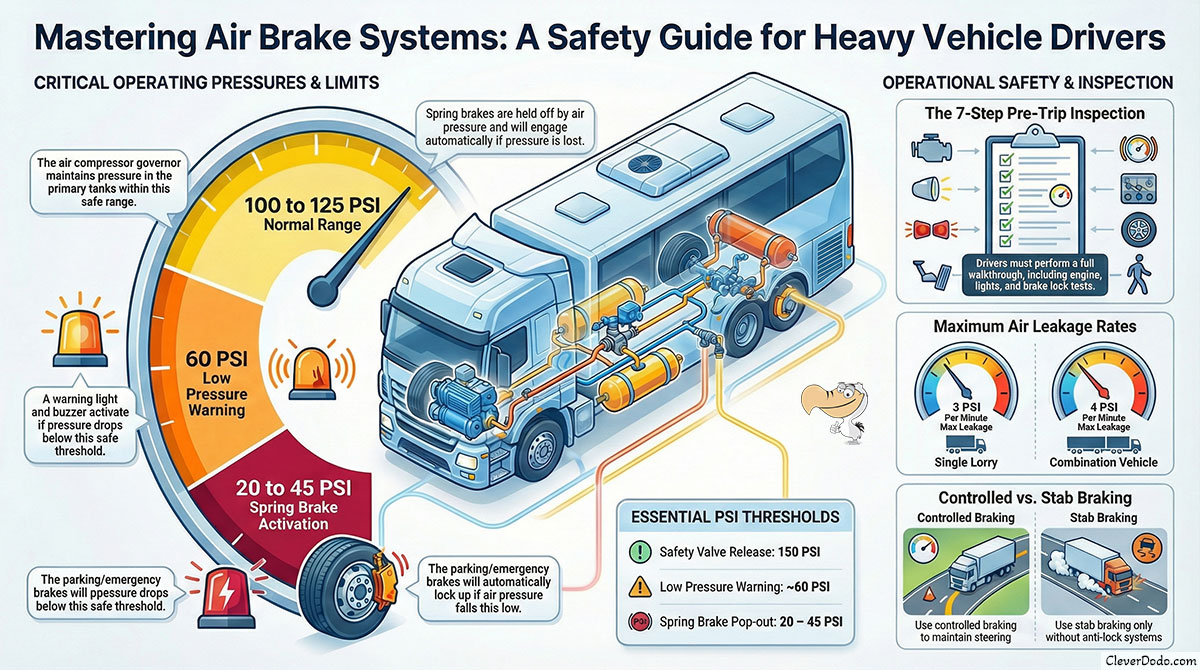

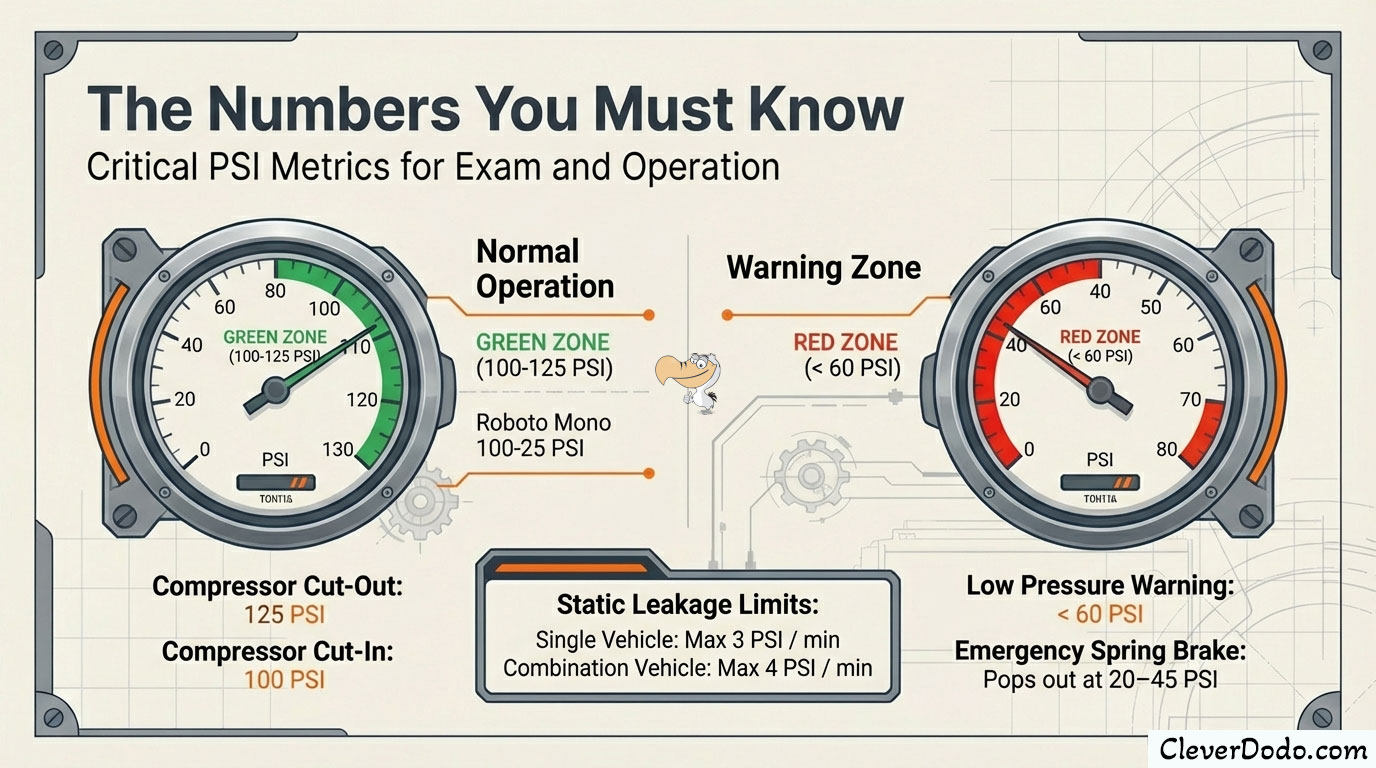

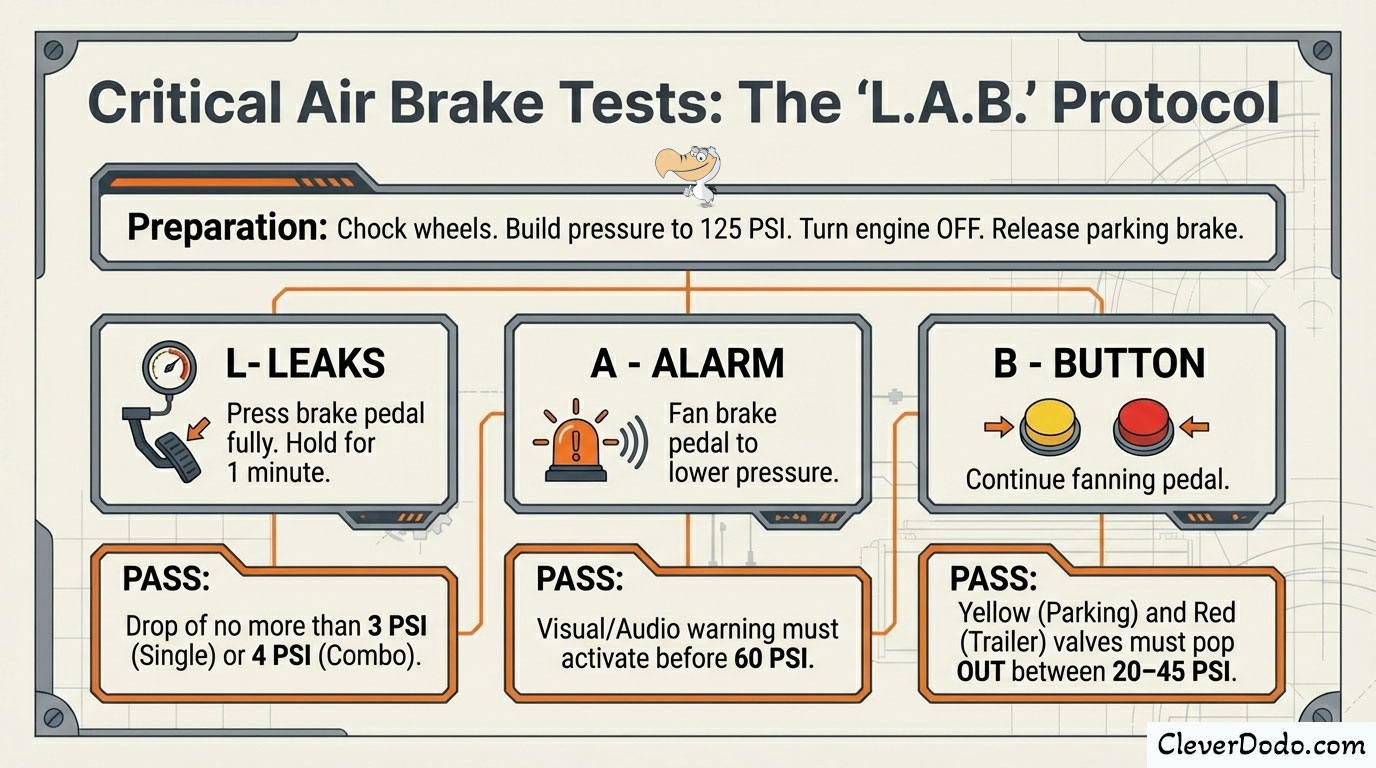

When a critical loss of air pressure occurs, the failsafe is triggered. Without enough air pressure to hold them back, the springs are automatically released, and the spring brakes are applied, bringing the vehicle to a stop. A low-pressure warning system alerts you when the pressure drops to around 60 PSI (pounds per square inch). If the pressure continues to fall, the parking brake valve will automatically engage the brakes when the pressure is between 20 and 45 PSI. This elegant design principle inverts the typical failure mode, ensuring that the most common type of system compromise defaults to a safe state—a stop—rather than a catastrophic loss of control.

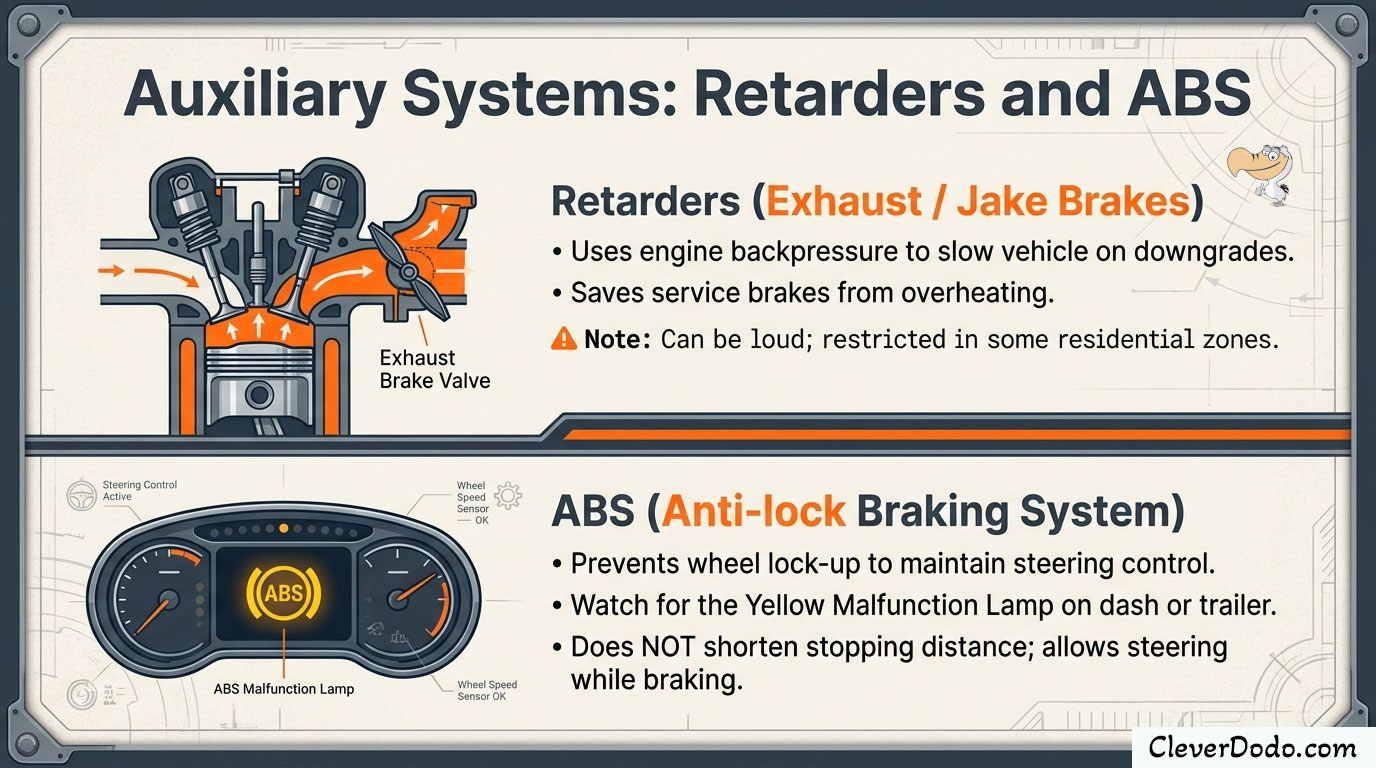

Your Anti-Lock Braking System (ABS) Is Not a Superpower

A common misconception among lorry drivers is that the Anti-lock Braking System (ABS) in their vehicle is a performance feature designed to make it stop in a shorter distance. The reality is quite different.

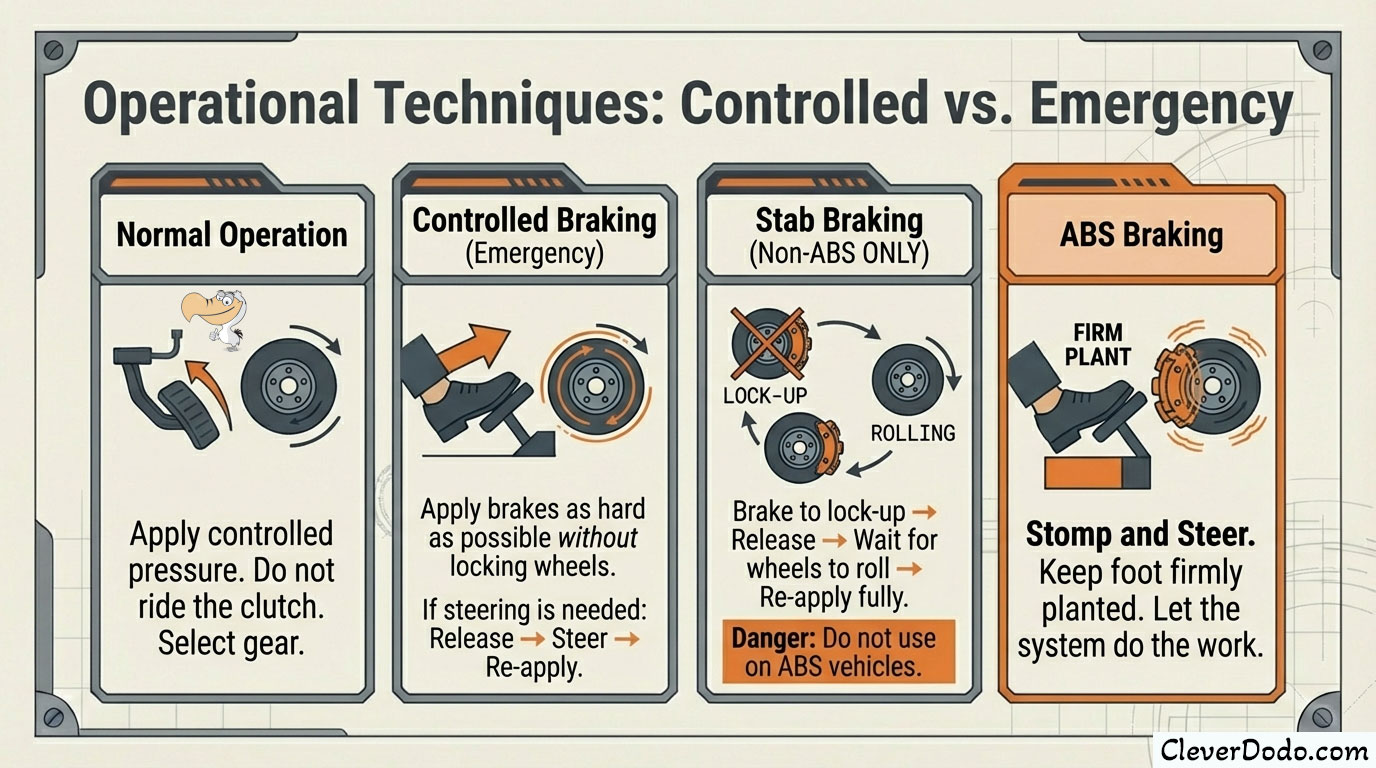

ABS does not necessarily decrease a vehicle's braking distance and is something we cover in the Clever Dodo Oral Mechanic Camion test as it's easy to misunderstand. The true and primary purpose of ABS is to prevent the wheels from locking up and skidding during hard braking. By preventing lock-up, the system allows the driver to maintain steering control while braking heavily. This ability to steer around an obstacle in an emergency stop is the system's key safety benefit.

What you need to remember is that ABS is a system designed for control, not for superior stopping power. It is NOT engineered to allow for driving faster or following other vehicles more closely. Even with ABS, the fundamental laws of physics governing momentum and friction still apply.

It Can Take Longer Than a Football Field to Stop a Heavy Lorry

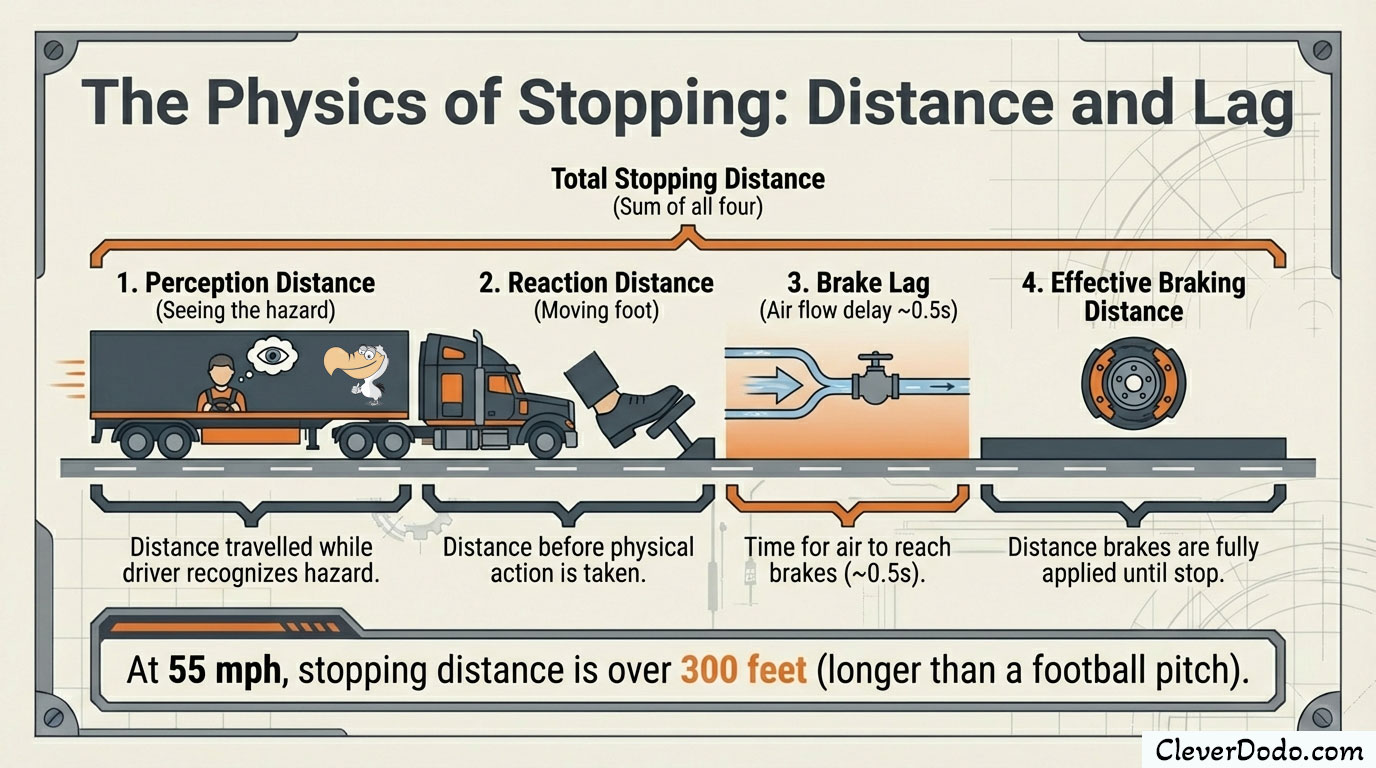

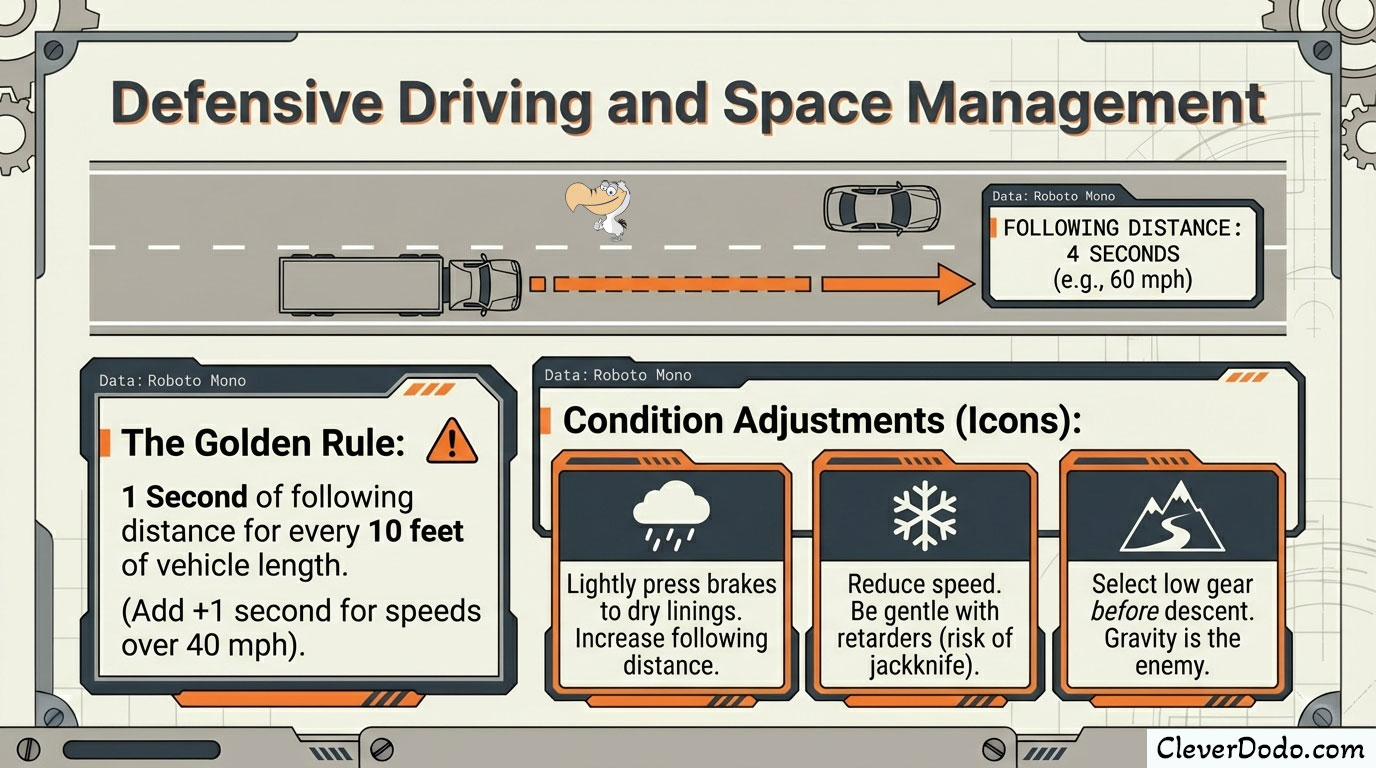

The sheer scale of stopping a fully loaded heavy vehicle is difficult to comprehend. For an average heavy vehicle traveling at 55 mph under good road conditions, the total stopping distance is more than 300 feet—a distance longer than a football field.

This massive distance is the sum of four distinct factors: Perception Distance, Reaction Distance, Brake Lag Distance, and Effective Braking Distance. For drivers of passenger cars, the last two factors are combined, because with a car’s hydraulic brakes, the brakes work instantly. With a truck’s air brakes, however, there is an added delay.

This delay creates the unique factor of Brake Lag Distance. Brake lag is the time it takes for compressed air to travel through the system's extensive network of hoses and valves to activate the brakes after you press the pedal. This delay alone can account for about 32 feet of travel distance at 55 mph. This fact underscores the immense forces at play and highlights why all drivers must give large lorries ample room to operate and stop safely.

The Gentle Touch That Can Lead to Total Failure

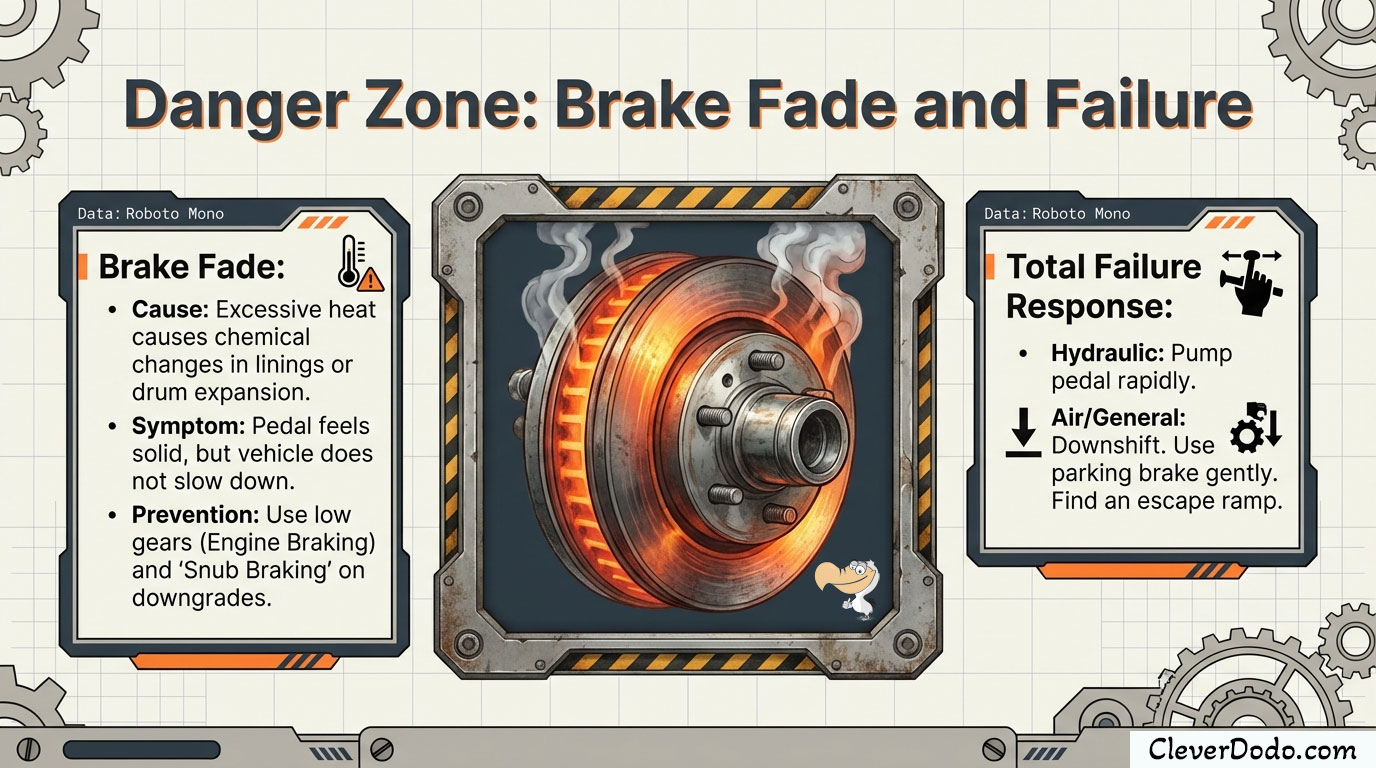

When descending a long, steep hill, your instinct might be to apply the brakes lightly and steadily to maintain a safe speed. This is one of the most dangerous things you can do, as it is a primary cause of a phenomenon known as "brake fade."

Brake fade is the loss of stopping power caused by excessive heat build-up in the brake pads and drums or rotors. Using a light, steady pressure on the brakes does not give them a chance to cool. The constant friction generates an enormous amount of heat, which can cause the friction surfaces to stop working correctly.

Brake fade is a very dangerous condition in which your brake pedal feels like it is working, but your vehicle does not stop.

The correct and safe technique for long downgrades is to first shift into a lower gear (retrograde), letting the engine and transmission handle most of the work of slowing the vehicle. Brakes should then be applied using an "on-and-off-braking" method: apply them firmly to reduce speed, then release them completely to allow air to flow over them for cooling before applying them again as needed.

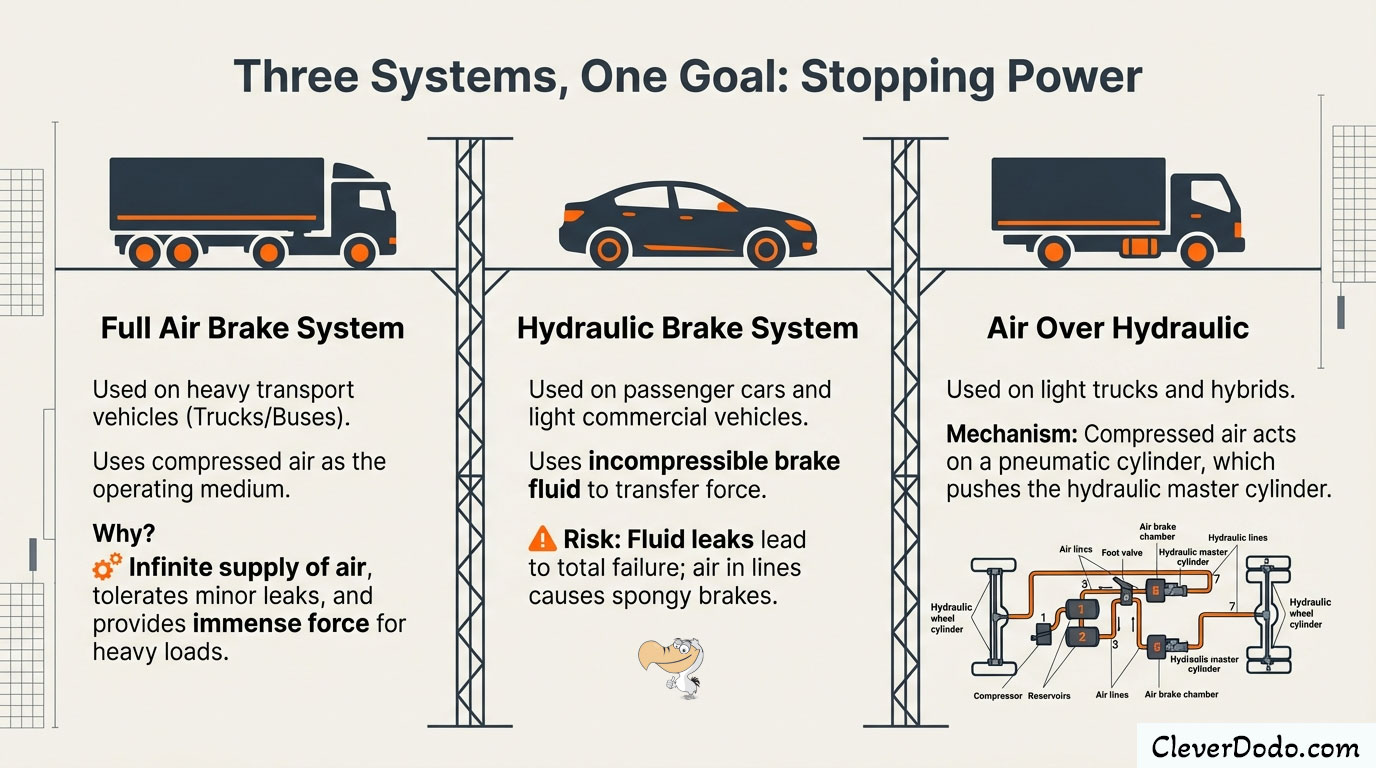

Why a Hissing Leak Isn't Always Your Worst Nightmare

Hearing a hissing sound from your brakes would be a cause for immediate alarm in a passenger car. In a standard hydraulic brake system, a leak means a loss of brake fluid; the incompressible liquid required to transfer force to the brakes. This results in a rapid and catastrophic loss of braking ability.

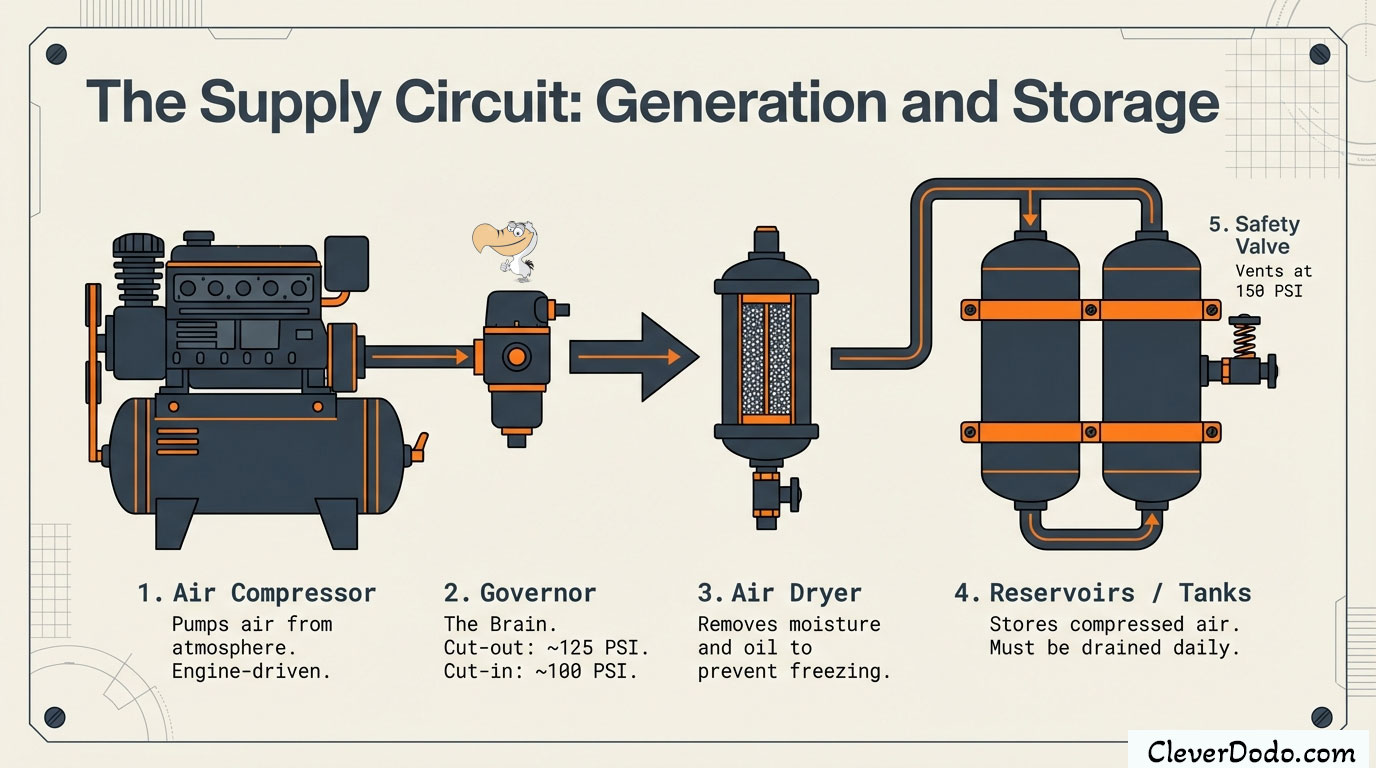

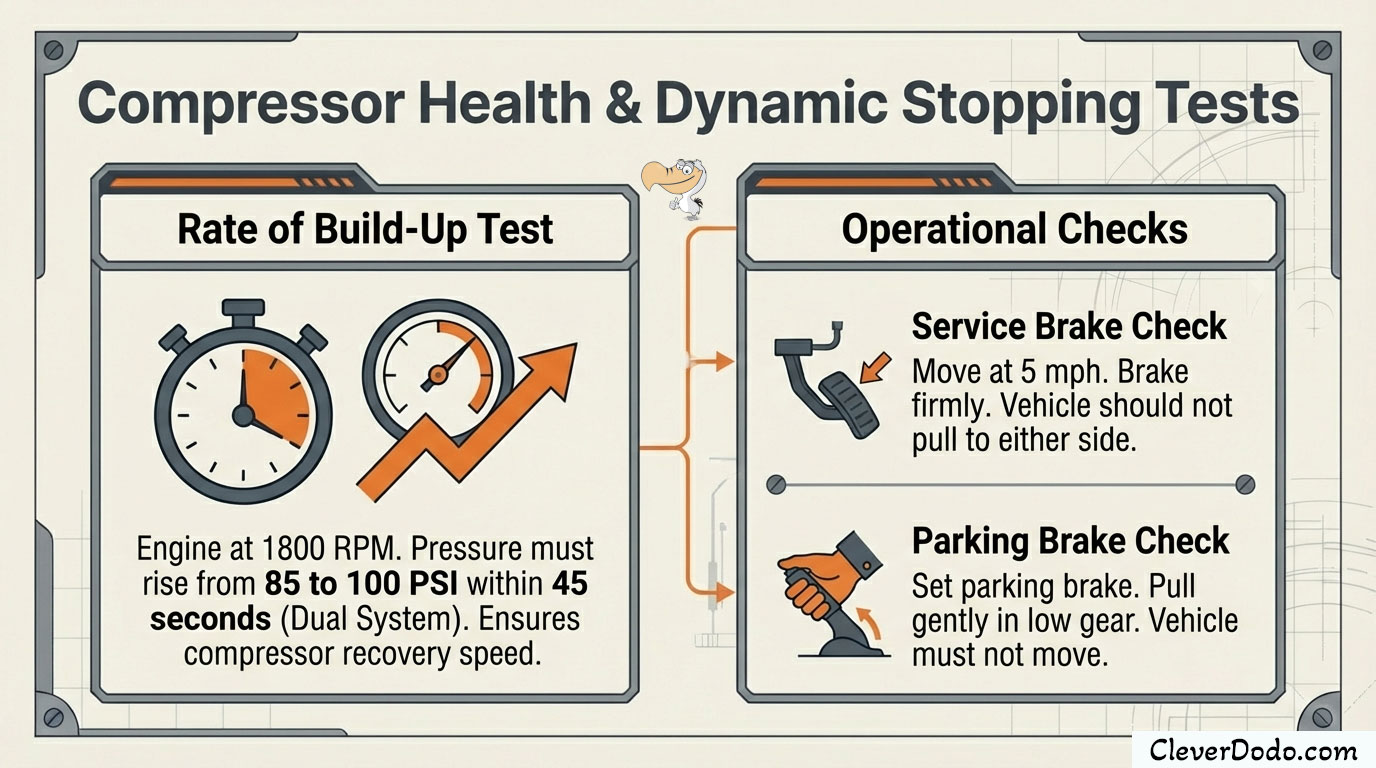

However, a leak in an air brake system is a different matter. While still a serious issue that must be repaired, it doesn't carry the same threat of immediate, total failure. This is because an air brake system has an engine-driven air compressor that is constantly working to pump air and replenish the supply in the storage tanks. Since air is always available, the brake failure due to leakage is the less concern in the air brake system.

The compressor can often compensate for minor leaks, giving you time to stop the vehicle safely. This design provides a layer of resilience and a warning period that is simply not present in a leaking hydraulic system.

NOTE: For more lessons like this, check out our oral mechanic camion course.

Oral Mechanic Lorry Test Prep Course

This course is specifically designed for drivers preparing for the oral mechanic lorry test. You’ll get 7 days of full access to clear and straightforward lessons, 6 quizzes covering the exact topics you’ll be tested on plus a realistic mock test so you know what to expect on test day.

Course Information